Rdf 2000 Reliability Data Handbook Template

Reliability Prediction Methods for Electronic ProductsReliaSoft June 2008In today’s competitive electronic products market, having higher reliability than competitors is one of the key factors for success. To obtain high product reliability, consideration of reliability issues should be integrated from the very beginning of the design phase. This leads to the concept of reliability prediction. Historically, this term has been used to denote the process of applying mathematical models and component data for the purpose of estimating the field reliability of a system before failure data are available for the system.

However, the objective of reliability prediction is not limited to predicting whether reliability goals, such as MTBF, can be reached. It can also be used for:. Identifying potential design weaknesses.

Evaluating the feasibility of a design. Comparing different designs and life-cycle costs. Providing models for system reliability/availability analysis.

Establishing goals for reliability tests. Aiding in business decisions such as budget allocation and scheduling.Once the prototype of a product is available, lab tests can be utilized to obtain more accurate reliability predictions.

Accurate prediction of the reliability of electronic products requires knowledge of the components, the design, the manufacturing process and the expected operating conditions. Several different approaches have been developed to achieve the reliability prediction of electronic systems and components. Each approach has its unique advantages and disadvantages. Among these approaches, three main categories are often used within government and industry: empirical (standards based), physics of failure and life testing. In this article, we will provide an overview of all three approaches.First, we will discuss empirical prediction methods, which are based on the experiences of engineers and on historical data. Several standards, such as MIL-HDBK-217, Bellcore/Telcordia, RDF 2000 and China 299B, are widely used for reliability prediction of electronic products. Next, we will discuss physics of failure methods, which are based on root-cause analysis of failure mechanisms, failure modes and stresses.

This approach is based upon an understanding of the physical properties of the materials, operation processes and technologies used in the design. Finally, we will discuss life testing methods, which are used to determine reliability by testing a relatively large number of samples at their specified operation stresses or higher stresses and using statistical models to analyze the data. Empirical (or Standards Based) Prediction MethodsEmpirical prediction methods are based on models developed from statistical curve fitting of historical failure data, which may have been collected in the field, in-house or from manufacturers. These methods tend to present good estimates of reliability for similar or slightly modified parts.

Some parameters in the curve function can be modified by integrating engineering knowledge. The assumption is made that system or equipment failure causes are inherently linked to components whose failures are independent of each other.

There are many different empirical methods that have been created for specific applications. Some have gained popularity within industry in the past three decades. The table below lists some of the available prediction standards and the following sections describe three of the most commonly used methods in a bit more detail.MIL-HDBK-217 Predictive MethodMIL-HDBK-217 is very well known in military and commercial industries. It is probably the most internationally recognized empirical prediction method, by far.

The latest version is MIL-HDBK-217F, which was released in 1991 and had two revisions: Notice 1 in 1992 and Notice 2 in 1995.The MIL-HDBK-217 predictive method consists of two parts; one is known as the parts count method and the other is called the part stressmethod 1. The parts count method assumes typical operating conditions of part complexity, ambient temperature, various electrical stresses, operation mode and environment (called reference conditions).

The failure rate for a part under the reference conditions is calculated as:where:. λ ref is the failure rate under the reference conditions. i is the number of parts.Since the parts may not operate under the reference conditions, the real operating conditions will result in failure rates that are different from those given by the “parts count” method. Therefore, the part stress method requires the specific part’s complexity, application stresses, environmental factors, etc. (called Pi factors).

For example, MIL-HDBK-217 provides many environmental conditions (expressed as π E) ranging from “ground benign” to “cannon launch.” The standard also provides multi-level quality specifications (expressed as π Q). The failure rate for parts under specific operating conditions can be calculated as:where:. π S is the stress factor. π T is the temperature factor.

π E is the environment factor. π Q is the quality factor. π A is the adjustment factor.Figure 1 shows an example using the MIL-HDBK-217 method (in ReliaSoft’s software) to predict the failure rate of a ceramic capacitor. According to the handbook, the failure rate of a commercial ceramic capacitor of 0.00068 mF capacitance with 80% operation voltage, working under 30 degrees ambient temperature and “ground benign” environment is 0.0216/10 6 hours. The corresponding MTBF (mean time before failure) or MTTF (mean time to failure) is estimated to be 46,140,368 hours.Figure 1: MIL-HDBK-217 capacitor failure rate example Bellcore/Telcordia Predictive MethodBellcore was a telecommunications research and development company that provided joint R&D and standards setting for AT&T and its co-owners.

Because of dissatisfaction with military handbook methods for their commercial products, Bellcore designed its own reliability prediction standard for commercial telecommunication products. In 1997, the company was acquired by Science Applications International Corporation (SAIC) and the company’s name was changed to Telcordia. Telcordia continues to revise and update the standard. The latest two updates are SR-332 Issue 1 (May 2001) and SR-332 Issue 2 (September 2006), both called “Reliability Prediction Procedure for Electronic Equipment.”The Bellcore/Telcordia standard assumes a serial model for electronic parts and it addresses failure rates at the infant mortality stage and at the steady-state stage with Methods I, II and III 2-3.

Method I is similar to the MIL-HDBK-217F parts count and part stress methods. The standard provides the generic failure rates and three part stress factors: device quality factor (π Q), electrical stress factor (π S) and temperature stress factor ( T). Method II is based on combining Method I predictions with data from laboratory tests performed in accordance with specific SR-332 criteria. Method III is a statistical prediction of failure rate based on field tracking data collected in accordance with specific SR-332 criteria. In Method III, the predicted failure rate is a weighted average of the generic steady-state failure rate and the field failure rate.Lambda Predict has implemented Methods I and II, and Method III will be added in the next version. Figure 2 shows an example in Lambda Predict using SR-332 Issue 1 to predict the failure rate of the same capacitor in the previous MIL-HDBK-217 example (shown in Figure 1). The failure rate is 9.654 Fits, which is 9.654 / 10 9 hours.

Design For Reliability Handbook Pdf

In order to compare the predicted results from MIL-HBK-217 and Bellcore SR-332, we must convert the failure rate to the same units. 9.654 Fits is 0.000965 / 10 6 hours. So the result of 0.0216 / 10 6 hours in MIL-HDBK-217 is much higher than the result in Bellcore/Telcordia SR-332. There are reasons for this variation. First, MIL-HDBK-217 is a standard used in the military so it is more conservative than the commercial standard.

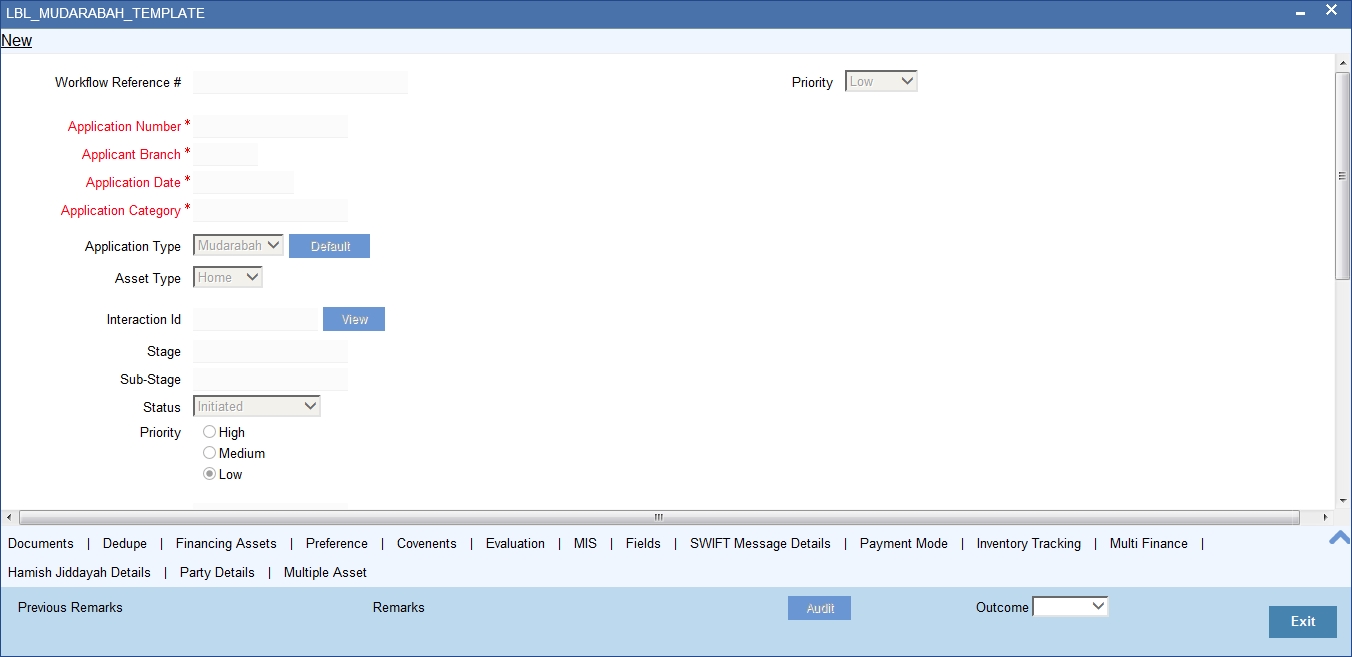

Second, the underlying methods are different and more factors that may affect the failure rate are considered in MIL-HDBK-217.Figure 2: Bellcore capacitor failure rate example RDF 2000 Predictive MethodRDF 2000 is a reliability data handbook developed by the French telecommunications industry. This standard provides reliability prediction models for a range of electronic components using cycling profiles and applicable phases as a basis for failure rate calculations 4.

RDF 2000 provides a unique approach to handle mission profiles in the failure rate prediction. Component failure is defined in terms of an empirical expression containing a base failure rate that is multiplied by factors influenced by mission profiles. These mission profiles contain information about how the component failure rate may be affected by operational cycling, ambient temperature variation and/or equipment switch on/off temperature variations. RDF 2000 disregards the wearout period and the infant mortality stage of product life based on the assumption that, for most electronic components, the wearout period is never reached because new products will replace the old ones before the wearout occurs. For components whose wearout period is not very far in the future, the normal life period has to be determined.

Rdf Data Format

The infant mortality stage failure rate is caused by a wide range of factors, such as manufacturing processes and material weakness, but can be eliminated by improving the design and production processes ( e.g.